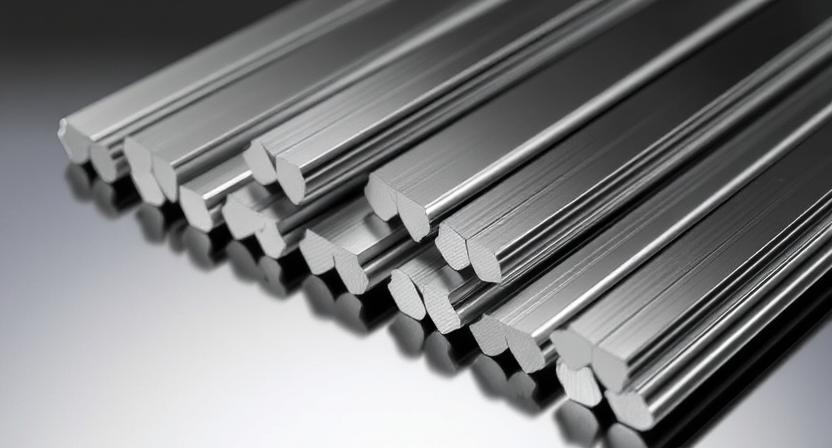

Staineless Steel 304 Springs

Stainless Steel 304H is an alloy of iron that contains chromium (typically 18-20%) and nickel (8-12%), with a higher carbon content compared to standard 304 stainless steel. The "H" designation stands for "high carbon," which enhances its strength and makes it particularly suitable for high-temperature environments. This material offers superior resistance to oxidation and corrosion, even in extreme conditions. Stainless Steel 304H is widely used in high-temperature settings and is highly regarded for its excellent mechanical properties. At Ferrobend, we understand that quality and reliability are paramount when selecting fasteners and springs for critical applications. Our Stainless Steel 304H fasteners and springs are manufactured with precision, ensuring they meet international standards for strength, durability, and corrosion resistance.

304H stainless steel is highly resistant to corrosion, ensuring that your fasteners and springs will continue to perform optimally even in aggressive environments. It resists oxidation, pitting, and crevice corrosion, making it ideal for use in chemical processing, marine, and food industries, where exposure to harsh elements is frequent. At Ferrobend, we take pride in our state-of-the-art manufacturing process. Our Stainless Steel 304H fasteners and springs are produced with precision engineering, which ensures that each component is dimensionally accurate and capable of performing under high mechanical stress. We also offer customization services to meet specific requirements in terms of size, shape, and finish.

Ferrobend ensures that all its stainless steel 304H fasteners and springs comply with international standards, including ASTM, ISO, and DIN. Our products are rigorously tested for quality control, so you can trust that they will perform at their best in any application.